La iluminación en un lugar de trabajo tiene una gran influencia en la funcionalidad y seguridad del espacio. Buena iluminación mantiene a sus empleados sanos y seguros de accidentes no deseados. Los lugares de trabajo como las obras de construcción y las instalaciones de fabricación suelen tener malos índices de visión.

Los trabajadores no ven bien las cosas debido al polvo y partículas que hay en la zona. Esto provoca accidentes graves. Y es posible que termine lidiando con facturas hospitalarias y demandas. En tales situaciones, OSHA interviene.

OSHA significa Administración de Salud y Seguridad Ocupacional. Es una organización que garantiza que su lugar de trabajo sea seguro y tenga fuentes de luz adecuadas.

Aquí, vorlane le orientará sobre los estándares de iluminación de OSHA para empresas industriales.

¿Cuál es el significado de una vela de pie?

La unidad de medida o componente de OSHA se conoce como Foot Candle. Si desea saber más sobre cuáles son exactamente los estándares de OSHA, entonces debería aprender sobre las velas de pie.

Niveles de iluminación recomendados por OSHA para oficinas

La luz tiene una gran influencia en la capacidad de los trabajadores para ver las pantallas de ordenador. Una buena cantidad de luz ayuda a los trabajadores a ver las computadoras fácilmente. Al mismo tiempo, una luz inadecuada provoca fatiga visual en los empleados mientras trabajan. El nivel de Luz que necesitas en una oficina. es muy diferente de la luz que necesitas en otro lugar de trabajo.

A continuación se detallan las pautas recomendadas por OSHA para iluminación de oficina:

- Utilice una luz de escritorio y luces de trabajo en cada mesa de trabajo.

- Aplicar persianas y cortinas en las ventanas. Protege su lugar de la luz brillante y brillante.

- Coloque las computadoras y las pantallas en el lado opuesto de la ventana, donde la luz no incida sobre las pantallas.

- Aplicar acabados mate y colores claros en techos y paredes para suavizar el reflejo de la luz y reducir el contraste.

Estándares de iluminación en el lugar de trabajo: limitación mínima

Las zonas de construcción necesitan una luminosidad de 5 velas. Las tiendas y plantas necesitan al menos el brillo de velas de 10 pies.

El nivel mínimo de luminosidad estándar varía en cada lugar de trabajo.

- Enfermería y lugar de primeros auxilios: 30 ft-c

- Salidas, pasillos y almacenes: 10 pies-c

- Túneles y pozos subterráneos: 5 pies-c

- Áreas de desechos, áreas de almacenamiento, plataformas de carga y áreas de reabastecimiento de combustible: 3 pies-c

En lugares comerciales comunes, el nivel mínimo de lux es el siguiente

- Salas de exposición, oficinas y laboratorios: 500 lux

- Talleres y fábricas: 750 lux

- Almacenes y muelles de carga: 300-400 lux

- Escaleras, pasillos y vestíbulos: 200 lux

- Pasillos de almacén: 100-200 lux

Estándares de iluminación de OSHA

Los requisitos de cubierta de luz de OSHA indican que se necesitan placas protectoras para todo tipo de luminarias.

Además, las luminarias deben contar con un escudo protector que las proteja contra eventos no deseados.

En particular, las áreas donde los artefactos de iluminación corren el riesgo de dañarse deben contener escudos protectores. El mismo consejo se aplica a las cajas de extracción, accesorios y cajas de conexiones.

Ventajas de seguir los estándares de iluminación de OSHA

Las normas de iluminación para el lugar de trabajo de OSHA básicamente presentan múltiples beneficios. Mejora significativamente la productividad laboral.

Además, un ambiente cómodo y sereno mejora el estado de ánimo del empleado. En última instancia, aumentará la productividad laboral y los resultados positivos. Todos estos factores se combinan y aportan productividad.

Los estándares de OSHA garantizan que su lugar de trabajo cumpla con todas las reglas de seguridad. La seguridad debe ser su prioridad en su lugar de trabajo. Porque determina la reputación de tu empresa como marca y de ti como empleador.

Además, nadie quiere colaborar con una empresa que no tiene ningún tipo de seguridad. Siempre se sienten inseguros mientras trabajan con usted.

Los riesgos de no cumplir con los estándares de iluminación de OSHA

Los inspectores de OSHA multan a la empresa si no sigue las normas de iluminación de OSHA.

En este caso, las empresas deben hacer frente a las siguientes multas:

- $13.494 costes si cometes una infracción grave de las normas

- $134,494 costos si no elimina la infracción anterior

- $134.937 costes si reincides en la infracción

Las empresas que no cumplen con las normas de iluminación de OSHA también tienen que enfrentar otros riesgos de pagar mucho dinero por

- En primer lugar, hay demandas de responsabilidad disponibles por lesiones personales o muerte por negligencia del trabajador o empleado. En segundo lugar, hay frecuentes inspecciones y citaciones en diversas áreas.

- En tercer lugar, los boicots de autoridades regulares como el DOL o la EPA.

- La empresa tiene mala reputación, lo que provoca la cancelación de contratos, la pérdida de proyectos y el boicot de futuras colaboraciones.

Debe recordar que tanto usted como sus contratistas siguen las reglas de OSHA. Su negligencia también resulta en tu caída.

Además, el proceso de gestión del cumplimiento de los contratistas lleva tiempo. Pero ahora contamos con un software de cumplimiento de contratistas, que hace que el proceso sea fácil y eficiente.

Requisitos de instalación de iluminación de OSHA

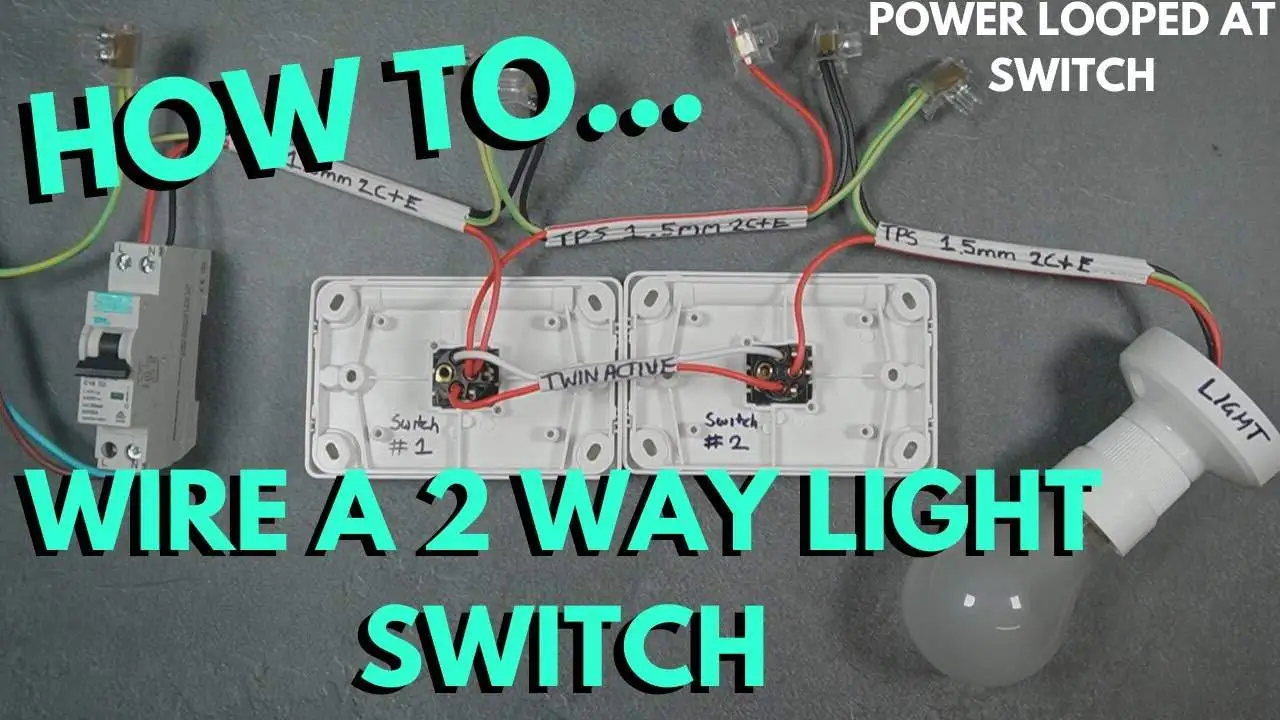

El 1910.305OSHA La norma presenta los requisitos de instalación de iluminación.

Las reglas y regulaciones para una lámpara permanente y una lámpara temporal son las mismas. Los conductores de tierra de la luz deben estar conectados a tierra de forma segura. No utilice conductos que tengan vapores o polvo inflamables para instalar ningún tipo de cableado.

Además, las luces temporales de menos de 600 voltios deben seguir más de cerca las normas de seguridad. Sólo deben utilizarse en reparaciones, remodelaciones o trabajos de emergencia.

Iluminación de tareas y de emergencia

Las luces de trabajo están especialmente diseñadas para apuntar la luz a un área específica.

Además, la Norma 1910 gestiona el uso de la iluminación de emergencia.

La mayoría de las reglas estándar para luces generales y luces de emergencia son las mismas. La única diferencia es que la instalación temporal de luz superior a 600 voltios se utiliza en trabajos de emergencia, pruebas o tareas temporales de construcción.

Las normas de iluminación de OSHA protegen a los trabajadores

Las normas de iluminación de seguridad de OSHA protegen a los empleados. Garantiza que el lugar de trabajo tenga suficiente luz para evitar lesiones y accidentes. Las normas de iluminación de seguridad de OSHA protegen al trabajador de la siguiente manera:

Identificación de los peligros

Una iluminación adecuada en un lugar de trabajo garantiza que el trabajador tenga visibilidad. Protege a los trabajadores de sufrir lesiones debido a obstáculos, mal funcionamiento del equipo y derrames.

Además, Buena iluminación También permite a los trabajadores identificar la situación de emergencia y responder a ella rápidamente.

Prevenir lesiones

Si el lugar de trabajo no cuenta con una iluminación adecuada, aumentarán las posibilidades de lesiones y accidentes. La iluminación inadecuada dificulta que los empleados vean las áreas con claridad.

Además, los estándares de iluminación de OSHA garantizan que debe haber suficiente brillo en el lugar de trabajo. Para que las personas puedan verlos fácilmente y protegerlos de lesiones y accidentes no deseados.

Iluminando el camino: el camino hacia el cumplimiento de una instalación de fabricación

En el corazón de la América industrial, una instalación de fabricación de tamaño mediano enfrentaba un desafío común: una iluminación obsoleta que reducía la productividad y generaba preocupaciones de seguridad. El camino hacia el cumplimiento de los estándares de iluminación de OSHA no consistió sólo en marcar casillas; se trataba de convertir un espacio de trabajo con poca iluminación en un faro de eficiencia y seguridad.

El reto

Los trabajadores se esforzaban por ver en áreas mal iluminadas, lo que provocaba errores y accidentes. La iluminación fluorescente existente era ineficiente, proyectaba sombras desiguales y elevaba los costos de energía.

La solución

La instalación se embarcó en una revisión integral de la iluminación. La clave de la transformación fue el cambio a la iluminación LED, que fue elegida por su eficiencia energética y longevidad. Se instaló iluminación específica para cada tarea en las estaciones de trabajo, lo que garantiza que se puedan realizar tareas precisas de forma segura y eficaz. Los LED superiores iluminaron las áreas comunes, mientras que los sensores de movimiento y las opciones regulables agregaron capas de eficiencia y control.

El resultado

Los resultados fueron esclarecedores. La instalación no sólo cumplió con los estrictos estándares de iluminación de OSHA, sino que también experimentó una disminución significativa en los accidentes laborales. Los trabajadores informaron menos fatiga visual y mayor satisfacción con su entorno mejorado. Los costes energéticos se desplomaron gracias a la eficiencia de la tecnología LED.

Conclusión

El estándar de iluminación de OSHA garantiza que su lugar de trabajo tenga un entorno funcional y seguro. Mantiene a los trabajadores a salvo de accidentes no deseados. Además, debe ser difícil cumplir con todas las normas y reglamentos en un lugar de trabajo.

Sin embargo, es esencial para un lugar de trabajo seguro. Por lo tanto, asegúrese de obtener ayuda de Vorlane para que su gestión de cumplimiento sea más fácil y rápida. Contáctenos ¡ahora!