The Ultimate Guide to Built-In Shelf Lighting

Explore guide to built-in shelf lighting. Learn about LED strips, puck lights, recessed lights, tape lights, and their installation tips for perfect ambiance.

Light Light-emitting diodes or LEDs refer to a source of light. When electrons pass through the material of a semiconductor, it turns on the light. LEDs come in different manufacturing types like flashlights, bulb lights, lamps, etc. Each product serves a different purpose.

Generally, LEDs are divided into two main types: Low-powered LEDs and High-powered LEDs.

LEDs contain a tiny chip and layers of semiconductor material. The package of LEDs also contains more than one chip, which is mounted over the thermal conductive material. This material is also called a heat sink and is covered with a lens. It forms a 7-9 mm thick device that can be utilized in several products and applications.

After this, LEDs are placed over a circuit board, enabling it to control light like diming, pre-set timing, and sensing. The circuit board also contains a heat sink which further enhances the thermal resistivity of the LED. After this, the LED and circuit are enclosed in a structure like a light bulb or light fixture to give it a more appropriate look.

In this innovative era, LED design requires more creativity. Before manufacturing LED light, it goes through a designing phase which includes details like color temperature, efficiency, light application, and brightness of the LED. Several factors like the size of the diode, material of the semiconductor, impurities types, and diode thickness in each layer significantly affect the attributes of the LED light.

Hence, if you want a customized design of the LED light, then reach out to our team of Vorlane to ensure your requests. We firmly believe that each request of clients has a doable solution.

The process of manufacturing LED lights involves the following four steps.

Semiconductor materials like arsenic, gallium, or Phosphor go under high temperature and pressure chambers. It liquifies the material, which is then deposited over a rod. It forms an ingot on the road. Wafers are then cut from the ingot, uniformed, and dipped in a special solution to eliminate contamination.

Manufacturers then add layers of crystal to the wafer with the help of the LPE process. The deposition of dopants and molten GaAsp mixture over the wafer grows crystal layers. They also add dopants in a furnace that contains dopants in gas form at high temperatures.

After this process, manufacturers deposit a photoresist substance over the wafer as it moves in a circle to develop a preset design on its surface. The substance hardens at almost 215°F temperature and exposes the wafer to the Ultraviolet light which creates a duplicate design on the photoresist.

It then fills the exposed areas with contact metal over the vacuum-sealed furnace at high temperatures. They put the LED in the chamber with a nitrogen atmosphere and inert hydrogen environment and then heat it to create a bond of metal with the surface of the wafer. In the end, manufacturers cut the wafers to make around 6000 dies.

They mounted the dies with a package. The backside of a die gets a coating of metal to create an electrical contact. The manufacturing is vacuum sealed in epoxy mold to create a desired shape.

LEDs offer a wide range of benefits. Some of those benefits include:

LEDs are used in a variety of devices and applications. Some of the applications include:

The art of creating LEDs starts with semiconductor fabrication, a process demanding unmatched precision. Achieving consistency across each wafer presents a formidable challenge, essential for the reliability and performance we’ve come to expect from LEDs.

Beyond the technical intricacies lies an economic battlefield. The materials essential for LED production, like gallium, don’t come cheap. Fluctuating prices add another layer of complexity, impacting the affordability of the final product.

In the fast-paced world of LED manufacturing, staying ahead means relentless innovation. But with advancement comes the pressure of competition and the hefty price tag of research and development, pushing manufacturers to their limits.

While LEDs are celebrated for their energy efficiency, the manufacturing process isn’t without environmental concerns. The quest for safer, more sustainable materials is ongoing, reflecting the industry’s commitment to reducing its ecological footprint.

As global demand for LEDs grows, scaling production while maintaining quality and sustainability standards is a juggling act. It’s a testament to the industry’s resilience and ingenuity, ensuring that the future remains bright, one LED at a time.

In the world of LED manufacturing, challenges abound—from the precision of semiconductor fabrication to the pressures of innovation and sustainability. Yet, it’s these very challenges that drive the industry forward, illuminating the path to a brighter, more efficient future.

The manufacturing industry is rapidly growing with advanced technology and innovative ideas. It was impossible to manufacture wafers with purity and uniformity a few years ago, however it is doable now. The integration of wafers in the light enhances the efficiency, brightness, and durability of the LEDs.

LEDs become a high demand and necessity for applications like undersea electronics and outer space gadgets. The process of incorporating more LEDs on a small chip makes them more efficient and demandable.

Vorlane is a leading brand of manufacturing high-quality LEDs and lighting solutions. Since the development of Vorlane, we have gained enormous popularity and won the hearts of various customers. You can give your full trust to our various manufacturing capabilities which include heat tempering to enhance glass specialty, strength, and services. Vorlane is a companion and one-stop solution for all your LED lighting solutions. Visit our website or reach out to us to book a meeting about understanding LED light systems.

Explore guide to built-in shelf lighting. Learn about LED strips, puck lights, recessed lights, tape lights, and their installation tips for perfect ambiance.

Explore the Global LED Lighting Market Report 2024 for insights on trends, growth drivers, and key players in the industry, including product segment and geographic

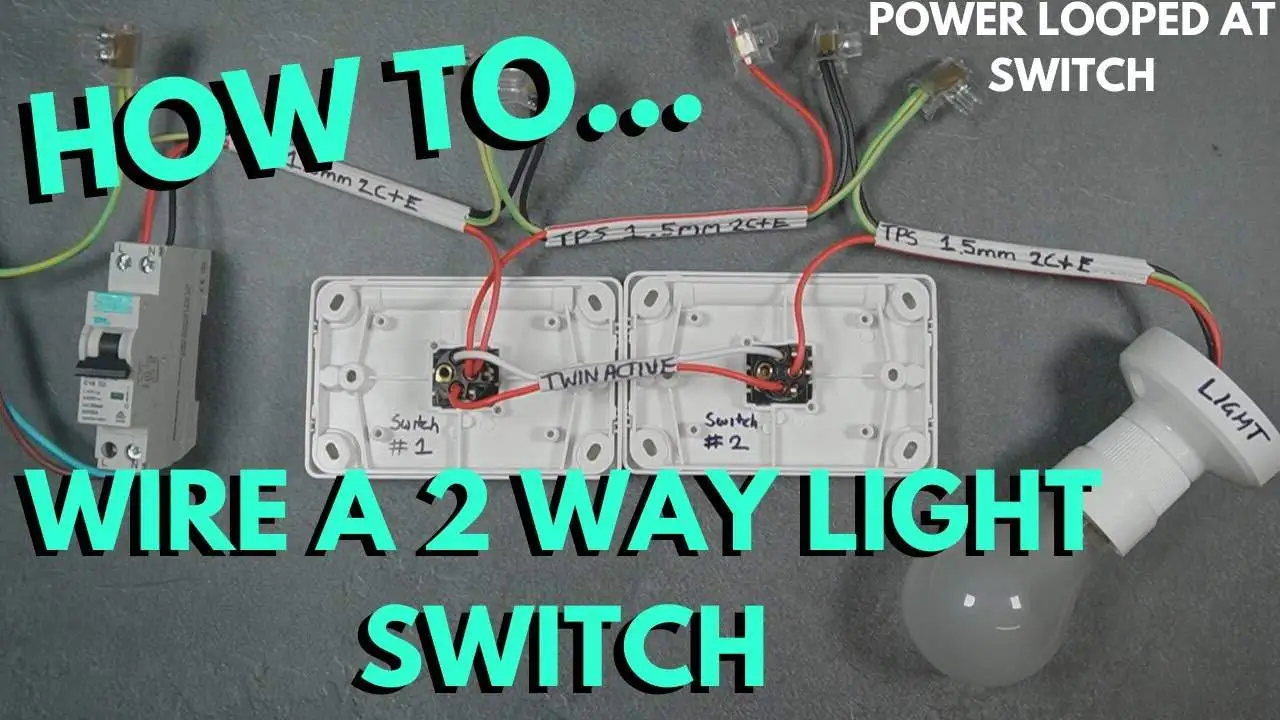

Learn how to wire a 2-way light switch effectively. This guide covers essential tools, step-by-step instructions, and safety measures for an installation.

| This LED Industry Research Report Is Worth 10,000 Dollars!Want to get reliable industry data to support your LED business planning? In this report, you will:

*Submit your email to download this file. Your personal info will not be shared to any 3rd-party person or organizations. |

WhatsApp us

*We respect your confidentiality and all information are protected.