Learn how Vorlane manage the whole manufacturing process of LED light and complete your order on budget and on time, batch after batch.

The LED driver is a self-contained power supply which determines the way of dimming, how many LEDs we can use, running voltage, and more critical specs. Vorlane designs, builds, and tests your LED drivers in house so we can ensure stable quality and performance of the LED lights.

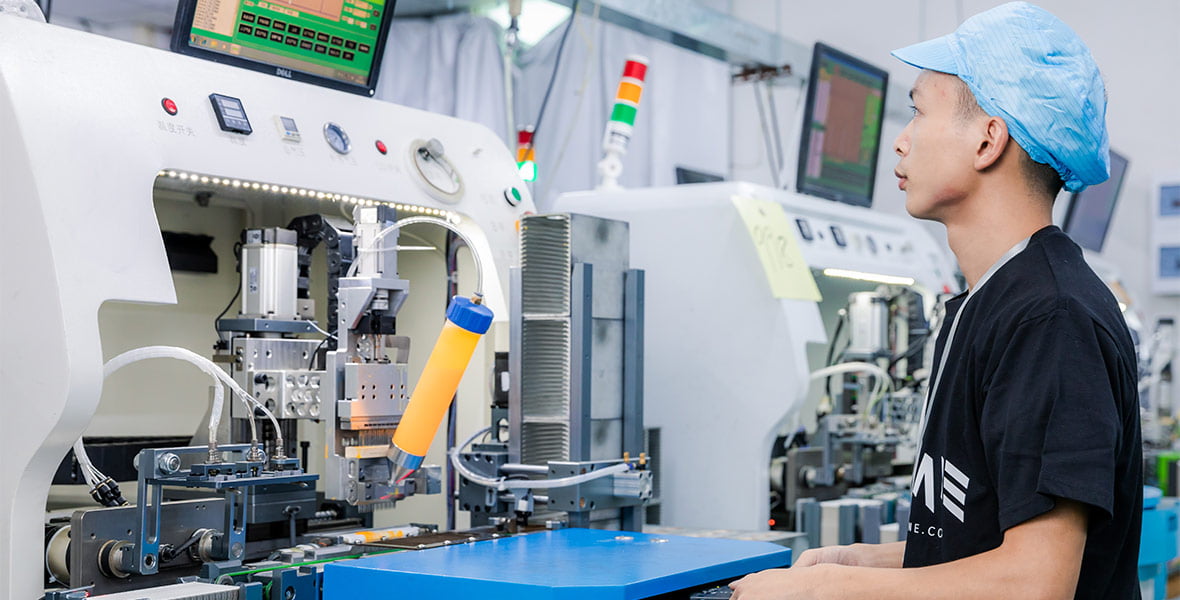

LED driver manufacturing takes extreme caution requiring our workers place and join all components together as per the design. Functional test is necessary after the procedure to make sure the LED driver is working normally.

We purchased LED chips from SANAN, the largest company supplying high quality LED chips. In this procedure, the automatic LED chip fixing machine helps to suck LED chips from the tray and mount them on the PCB in a scientific order and realize automatic defective detection.

With chips correctly arranged on the PCB, the wire bonder is now assisting to turn the whole PCB into a closed circuit, so that the LEDs start to light when the driver brings specific voltage and current. Using 99.9% pure gold as the bonding wire, we are guaranteeing the bond doesn’t rust easily and lasts longer.

The bonded PCB will then send to the color toning procedure, where the LEDs can shine any color our clients want. By adjusting the color of the glue as per the PANTONE color, we are assuring you that we can bring exactly the same color in all batches.

All LEDs will be sorted by current, voltage, and color automatically with the help of the automatic spectrophotometer. In this process, any malfunctioning LEDs will also be removed. Then all the LEDs with the same spec will be connected with each other as a strip and shipped to the next workshop.

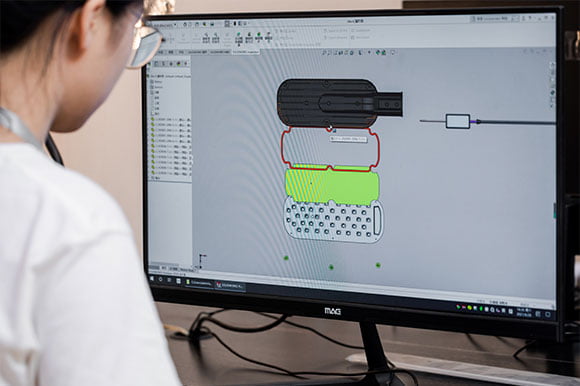

Cooperating with top mold designing agency, Vorlane is bringing the LED light housing design to life on the basis of thorough analysis of manufacturing flexibility. With a properly designed mold, the molding process is guaranteed to be efficient and safe.

Applying the most sophisticated CNC machines and water jet cutters, Vorlane makes high precision mold with tight tolerance within ±0.01mm, so that the designed housing can be perfectly molded.

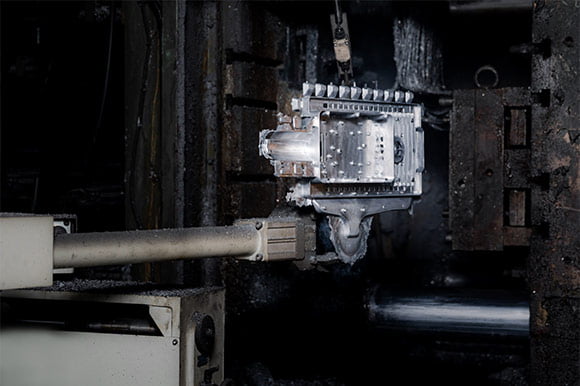

In this process, melted metal (mostly aluminum) is injected into the mold cavity to form a shape of the housing. By strictly controlling the pressure and time, we are avoiding the housing from deformation and cracks.

We purchased plastic pellets from Thailand to make sure we get the best plastic performance at the best price.

Using top injection molding machines YIZUMI, Vorlane made the injection molding procedure reliable and precise.

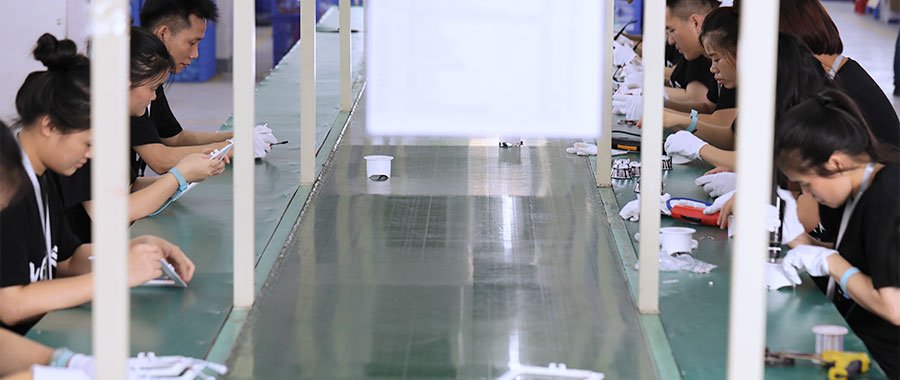

With LED drivers, LEDs, and housing prepared, the assembly workshop is here for joining all the parts together.

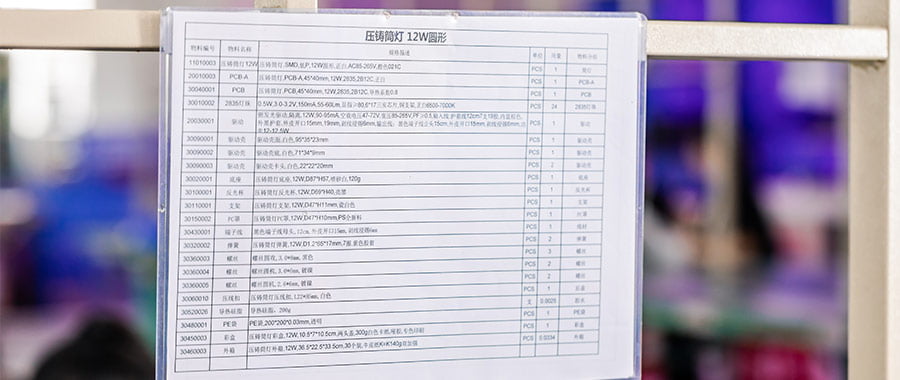

Vorlane follows standardized assembly process with the help of BOM sheet for each mode of LED light, indicating the correct way and standard to assemble the light. All workers must finish the assembly job as per the sheet

The assembled lights will be subject to a 24-hour aging test under high voltage of 2700V~3500V. Only when the lights pass the test will them be sent to the packaging lines.

Vorlane’s LED light and services give you an absolute edge over your competitors.

| This LED Industry Research Report Is Worth 10,000 Dollars!Want to get reliable industry data to support your LED business planning? In this report, you will:

*Submit your email to download this file. Your personal info will not be shared to any 3rd-party person or organizations. |

WhatsApp us

*We respect your confidentiality and all information are protected.