Vorlane factory has passed ISO 9001 certification and applied the principles as our guidelines in our daily manufacturing processes.

Cooperating with notable LED suppliers including SANAN, PHILIPS, CREE, Vorlane quality is proven reliable by our clients.

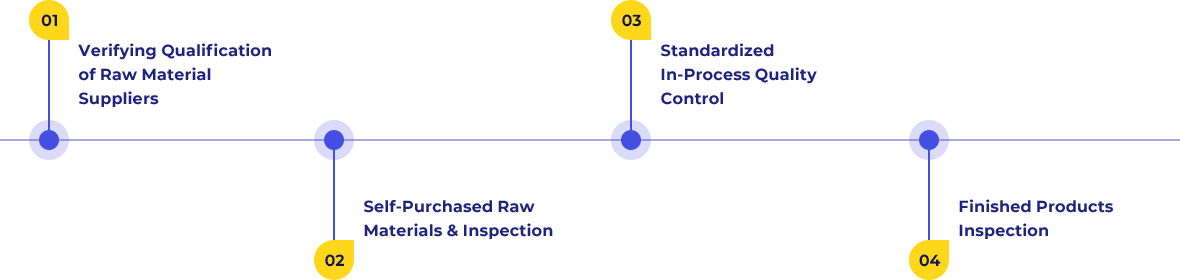

From raw material inspection to semi-products inspection, LED components to finished products testing, we trust the power of standardized process.

We care about the quality of LED light. That’s why we focus on every detail of every component that makes up a perfect LED light.

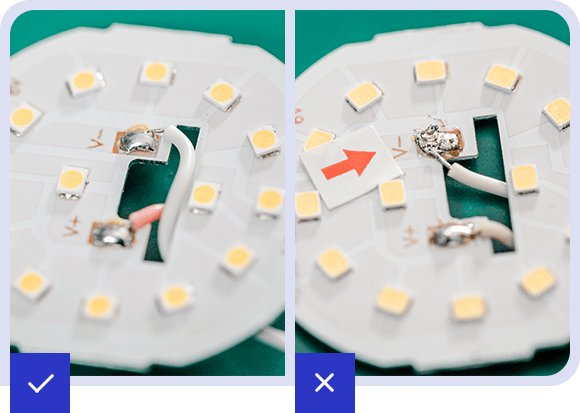

We use UL certified LED drivers. Every component must be placed and welded correctly so as to keep the LED working under certain max wattage, correct dimming way, and right power factor.

LED manufacturing requires expertise and caution. From baking to examining the right color, inspecting placement of LED to wire bonding, we have detailed standards for each insto follow for each inspection step, by doing so we can 100% remove any LED with flaw.

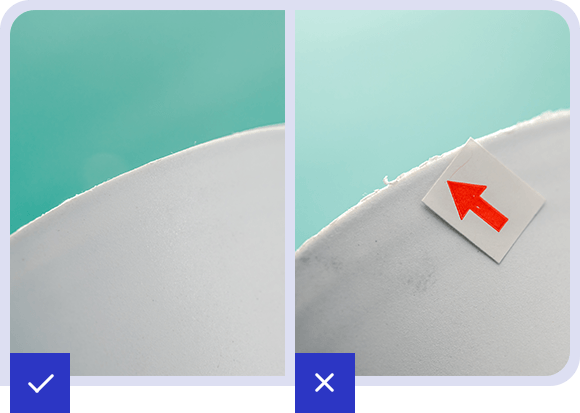

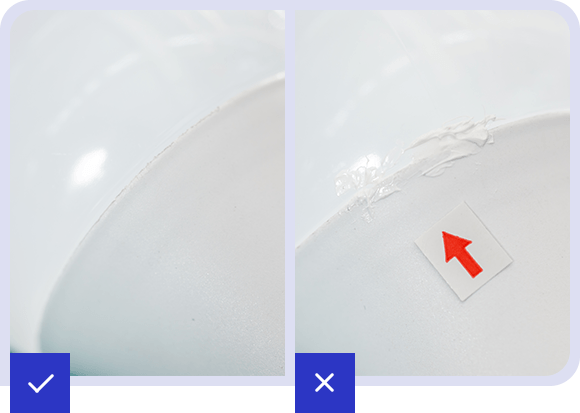

Lighting fixture forms the first impression so we never overlook any tiny flaw. Be it the fur made by casting or injection molding process, the uneven electroplated aluminum layer, size or spec deviation, we just don’t allow any of these happen and won’t let any product with such flaws pass to the next process.

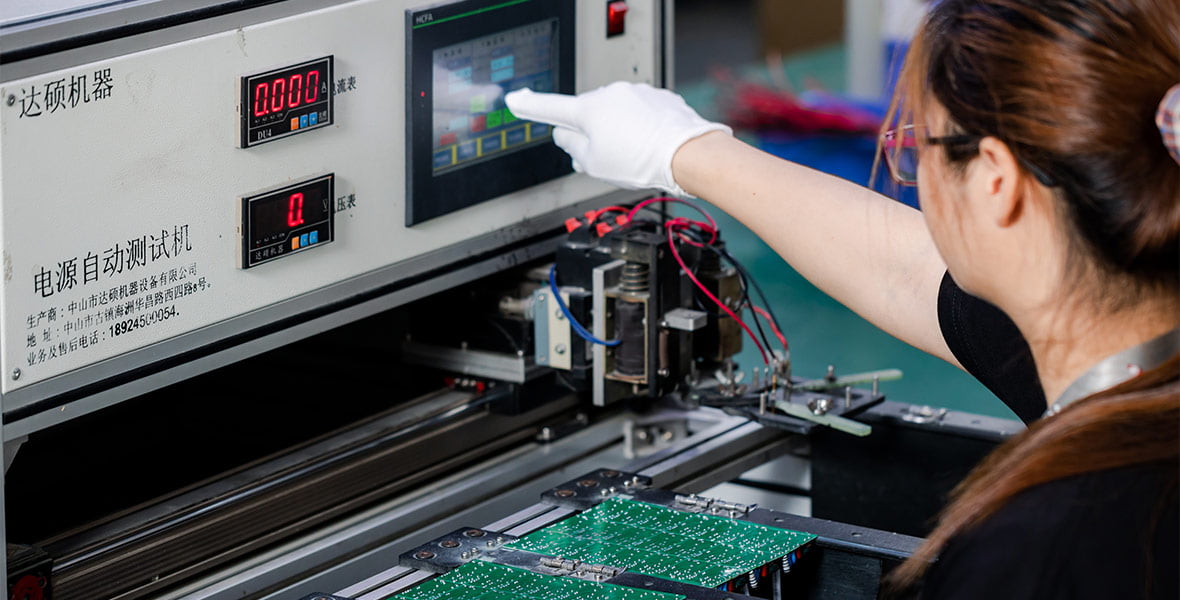

The sample acts as the bridge between quality components and quality mass production. Here in Vorlane, our unique approach is to test the sample again and again under the most severe condition so that all the components are working to ensure the performance.

Once the sample stand the tests, the QC team is responsible for recording its spec and providing BOM sheet for the mass production procedure.

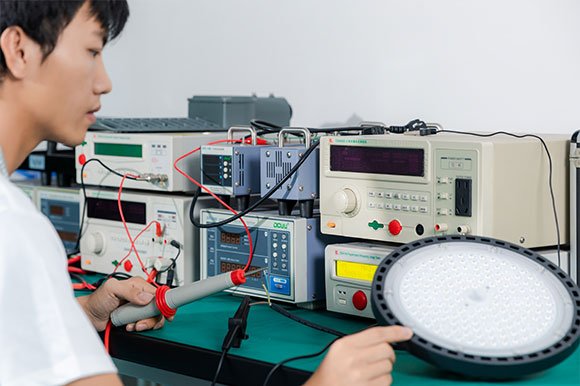

To ensure our sample is in line with your requirement, we conduct tests using photometric integrating sphere to deliver spectral test report that all the specs are clearly listed:

CRI, Color temperature, color fidelity

Luminous flux, luminous efficiency

Stimulating surge current and lightening using lightning & surge generator to test if the LED light maintain proper function.

Applying a high level of alternating currents (AC) or direct currents (DC) from 2700V to 3500V to the light and measure the reaction of the light.

Connecting the sample light to direct current for accurate electrical parameters including power efficiency, voltage, current, watt, power factors, etc.

Dropping the light from 1m from the ground and putting it on the vibration shelf to test if it stand the crash and still work.

Vorlane LED lights have survived the tests stimulating the harshest conditions so you can rest assured that the lights work even in the developing area with unstable power connection.

Lighten and record the total lifespan of every light

Using multi-channel temperature record to stimulate -30~100 degree celsius.

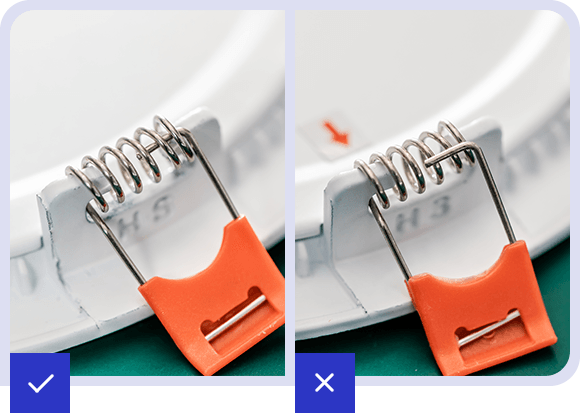

Correct assembly makes the light perform and make sure the safety of end users, Vorlane pay special attention to the assembly process and regulate every operation of the workers.

It is Vorlane’s revolution that each operation is subject to both method and standard. In all the details, we weed out the unqualified lights to make sure what you received is flawless.

Vorlane’s LED light and services give you an absolute edge over your competitors.

| This LED Industry Research Report Is Worth 10,000 Dollars!Want to get reliable industry data to support your LED business planning? In this report, you will:

*Submit your email to download this file. Your personal info will not be shared to any 3rd-party person or organizations. |

WhatsApp us

*We respect your confidentiality and all information are protected.