The Ultimate Guide to Built-In Shelf Lighting

Explore guide to built-in shelf lighting. Learn about LED strips, puck lights, recessed lights, tape lights, and their installation tips for perfect ambiance.

Today, we have different electrical installations in our homes and offices. These installations help us with our daily lives and make us productive. Technology makes these electrical devices important for all households and organizations.

Amidst all these installations, we have junction boxes. These are crucial for the safe and stable wiring connections in our homes and offices. They keep the wiring safe from heat damage, short circuits, and electric current leakage.

In this post, we will discuss the significance of junction boxes in depth so that you can learn more about them. You might need a junction box for your place shortly! So, let’s start this post and see what we can add to the insights of junction boxes.

Vorlane defines junction boxes as enclosures for protecting and safeguarding electrical connections. They are also suitable for organizing big loops of wires in a place. A junction box also combines different cables when needed. The vast majority of junction boxes are also underground to make a place aesthetically appealing and organized.

A junction box is necessary to protect electrical connections from environmental damage in the long run.

There is more than one type of junction box. We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these junction boxes based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

Plastic Junction Boxes: Known for their lightweight bodies, these junction boxes are ubiquitous in different industries. They are also heavily present in residential and commercial areas, where we use them to protect the place and wiring connections from risks and damage.

Plastic junction boxes are non-conductive and don’t let the eclectic current pass through them. This feature makes it highly dependable for residential and commercial applications. Other than this, they are corrosion-resistant. This means that in damp and moist environments, they easily withstand the risk of corrosion.

Metal Junction Boxes: Metal makes these boxes sturdy and highly durable. The strength of metals provides these boxes with multiple features. Take fire and mechanical damage, for instance. Even plastic containers cannot endure the damage in such highly unfavorable circumstances.

Therefore, we use metallic junction boxes in areas with a high risk of environmental and electrical damage. They are not affordable, like plastic junction boxes; however, they are more promising than plastic ones in terms of guaranteed corrosion resistance.

The size of a junction box varies with the number of wiring connections. We use junction boxes of different sizes in residential and commercial areas. The shape of junction boxes also matters according to the number of wires.

We have rectangular, square, octagonal, and round metal junction boxes available today. Every junction box complies with a particular wiring system, so we decide what type will prove reliable based on that system. Considering the size and shape of a junction box is essential since they can create problems for the wiring system, making it more vulnerable and risky.

As you know, junction boxes are essential when it comes to the successful protection and management of wiring systems. These ensure that the wiring system is protected from environmental damage and that people are saved.

Therefore, we need to consider some essential factors regarding junction boxes. We will instruct you on installing a junction box safely and securely without using expensive professional assistance.

The first step is to mount the box. You will detach the wires from each other and try to loosen them to fit into the box easily. Make sure you are equipping the box with an anchor so that it can stay firm in its place in the long run. Fix the box with screws to make it more steady, which will protect the box and the wiring it is holding in unfavorable circumstances.

It’s time to use the clamps. To prevent each cable from getting tangled, we will give it its clamp. Cable clamps come with most junction boxes, so we don’t have to pay extra.

Use the threaded end of clamps by passing them through a knockout hole and taking them inside the box. Round-shaped nuts need to be tightened so the clamps can successfully manage the wires in the box.

Now, you will secure the cables by combining them with the clamps. There should be a considerable margin of about 1/4 inch between the box and the clamp.

The individual conducting wires would go well with a distance of 6 inches from the box. You can also trim the wires to create more space in the box and keep them organized in the long run. Securing of cables happens by tightening the screws.

However, you don’t need to overtighten them, as doing so can compromise them, making them vulnerable to current leaks and short circuits. Instead, use spring tabs of junction boxes for wire clamping. This omits the need for manual tightening, which can be risky if overdone.

When joining the wires, you need to adhere to the manufacturer’s guidelines. It would be best if you also had connectors for this purpose. We always need to join green copper-insulated wires. If you are using a metallic box, then use a 6-inch pigtail.

You can also use a ground wire of 6 inches for grounding the wires. The loose end of the wire goes with the pigtail, and then you will screw the box. We use special green wire connectors to combine the grounded wires. White neutral wires are combined with black hot wires with the help of a wire connector. You can also combine red hot wires with these wires if needed.

The last step is to fold the wires so they don’t pop out of the box after some time. This takes place gently and carefully so that the cables are not compromised. We generally use only two screws for this purpose. Now, start the power to the circuit by tuning the circuit breaker.

Junction boxes are versatile in their applications. This means that we don’t only use them for wire protection and management. You should also know about their many other uses.

We need junction boxes for ceiling and wall fixtures. These boxes are safe to use and guarantee the risk-free functioning of fixtures. They also adapt to the fixture’s weight. Chandeliers and pendant lights use junction boxes for the same purpose. By using these boxes, we guarantee better connection stability.

LEDs are worldwide; therefore, we need junction boxes to enhance performance and efficiency. These junction boxes contain drivers and transformers that support LED installations. This is handy when we consider retrofitting commercial and residential places where the electrical system doesn’t usually comply with LEDs. Therefore, we need junction boxes to reduce such complications.

Junction boxes are highly reliable for outdoor usage. They are water-resistant, so outside weather does not damage them. We need junction boxes for garden lights, outdoor fixtures, and security lighting. These junction boxes remain efficient and dependable regardless of weather fluctuations like heavy rain and hot temperatures.

We also use junction boxes for aesthetics. For example, in landscape and pathway lighting, we use underground junction boxes to enhance the appeal of such lighting. These boxes manage the wires underground and never show up, making them highly dependable for resorts and hotels.

In architecture, we use junction boxes for track and accent lighting. These lights secure them and make them efficient in performing in this sector. Besides, these also enhance wiring management, which adds to the ease of this industry at a much deeper level.

We rely on junction boxes even for our intelligent lighting systems. This shows that these junction boxes also comply with advanced tech. We can easily install intelligent lighting systems with the help of these boxes. Additionally, controllers and hubs are needed to make them work in this case. These components are connected to the space’s electrical network, while the junction box is the meeting point of all wiring connections. This is how it makes the system risk-free and stable.

Junction boxes are a massive asset for managing and safeguarding wiring systems because of their versatility and multi-purpose ness. This guide will help you get the best possible junction box for yourself without any struggle when you need one.

Follow the instructions, and you’ll soon find a reliable junction box! Or contact us at Vorlane for experts and professionals in light fixtures and installations.

Explore guide to built-in shelf lighting. Learn about LED strips, puck lights, recessed lights, tape lights, and their installation tips for perfect ambiance.

Explore the Global LED Lighting Market Report 2024 for insights on trends, growth drivers, and key players in the industry, including product segment and geographic

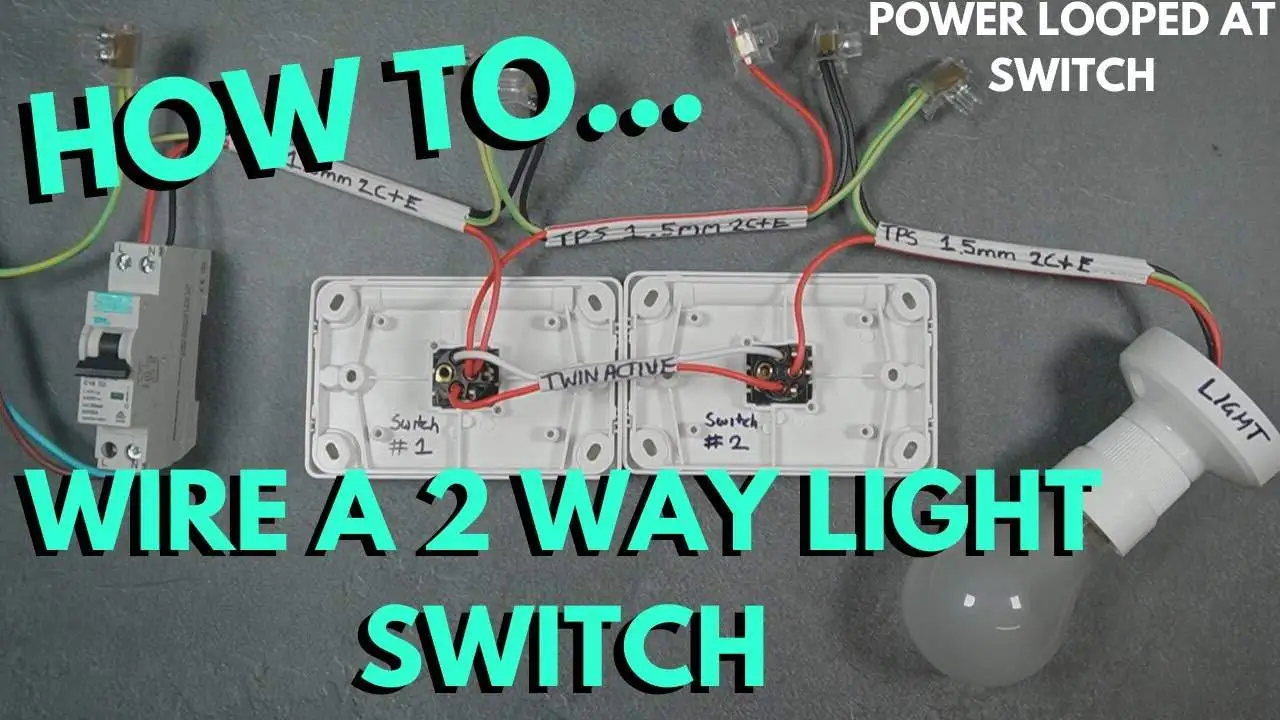

Learn how to wire a 2-way light switch effectively. This guide covers essential tools, step-by-step instructions, and safety measures for an installation.

| This LED Industry Research Report Is Worth 10,000 Dollars!Want to get reliable industry data to support your LED business planning? In this report, you will:

*Submit your email to download this file. Your personal info will not be shared to any 3rd-party person or organizations. |

WhatsApp us

*We respect your confidentiality and all information are protected.