Do you ever stop to think about how your favorite products are made? For example, how a tube light is manufactured? Do you want to know more about it?

Tubelights are manufactured through a series of steps that involve the use of materials, machinery, and processes. Like any other product, tube lights start as raw materials and are then transformed into a finished product.

In this article, we will discuss the process of tube light manufacturing and how each step plays its part in creating a working product that is safe for use. We will also give you some tips on how to choose a tube light manufacturer. Let’s get started!

The History of Tubelight Evolution

20th Century

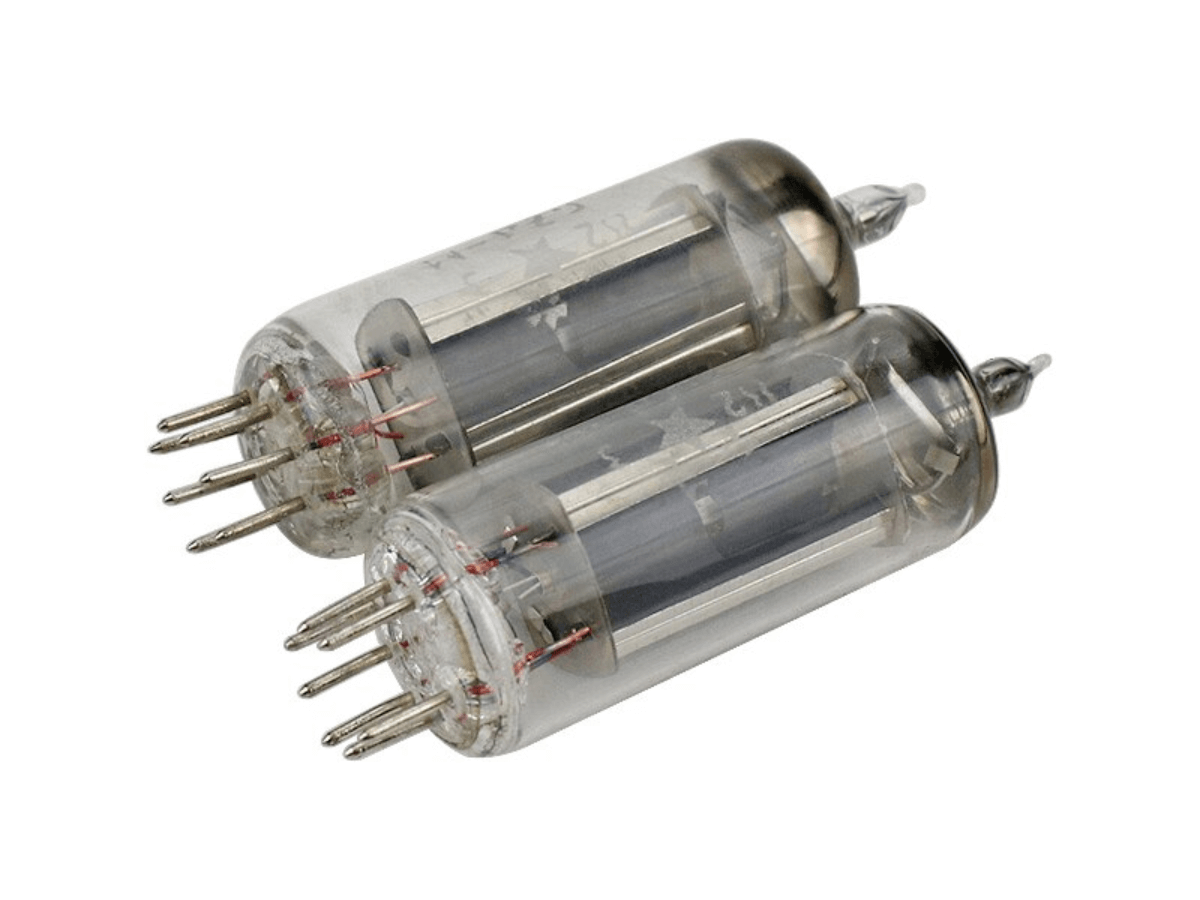

The tube light was invented in the early 20th century by French engineer Paul-Louis Weiller. At the time, most lights were still powered by gas. Weiller saw the potential for electricity to revolutionize lighting, His design consisted of a glass tube filled with mercury vapor. When an electric current was passed through the tube, the mercury vapor would glow, producing light.

1927

Weiller’s invention was met with skepticism from the scientific community. Many doubted that his light bulb would be able to produce enough light to be useful. But Weiller persevered, and in 1927 he finally succeeded in making a tube light that was bright enough to be used in households. Tubelights quickly became popular, and they soon replaced gas lights.

Today

Today, tube lights are an essential part of any light fixture. Thanks to their efficiency and durability, they have become one of the most popular types of bulbs used today. And while they may seem like a simple invention, tube lights have truly revolutionized the way we see the world.

The Basics of Tubelight Manufacturing

Tubelights are a type of fluorescent light that uses a tubular shape to contain light-producing gases. The tubular shape helps to evenly distribute the light and makes the tube light more efficient than other types of fluorescent lights.

Tubelights are made by enclosing a gas-filled tube in a glass or plastic enclosure. The gas-filled tube is usually made of quartz or phosphorus, and the enclosure is typically made of glass or plastic.

A tube light can last for up to 10,000 hours, making it a very long-lasting and energy-efficient lighting option. Tubelights are widely used in both commercial and residential settings and are an increasingly popular choice for those looking to save energy and money.

Main Features of a Tubelight

The main feature of a tube light is the following:

| Input Voltage | Tubelights are typically powered by an AC voltage of between 120 and 277 volts. This allows one to use them with most existing electrical wiring setups. |

| Lumens Output | The amount of light emitted from a tube light is measured in lumens (lm). A higher lumen output means the bulb will be brighter, while a lower lumen output will produce a dimmer light. |

| Color Rendering Index (CRI) | A higher CRI means that colors, such as skin tones and clothing hues, will appear more accurate and natural. |

| Driver Types | Tube lights can be powered by different types of drivers, such as ballasts or electronic drivers. |

| Voltage Operating Range | Tubelights are designed to operate within a specific range of AC voltages. This allows one to use them in different electrical systems without needing to buy new bulbs. |

| High Surge Protection | Many tube lights are designed with high surge protection, which helps to protect the bulb from sudden spikes in voltage. |

| Optics | Tube lights are available with different optics, such as narrow-angle or wide-angle beams. This allows one to choose the right bulb for one specific application and lighting needs. |

Input Voltage

Tubelights are typically powered by an AC voltage of between 120 and 277 volts. This allows one to use them with most existing electrical wiring setups.

Lumens Output

The amount of light emitted from a tube light is measured in lumens (lm). A higher lumen output means the bulb will be brighter, while a lower lumen output will produce a dimmer light.

Color Rendering Index (CRI)

The CRI of a tube light measures how accurately colors appear when viewed under the light source. A higher CRI means that colors, such as skin tones and clothing hues, will appear more accurate and natural.

Driver Types

Tube lights can be powered by different types of drivers, such as ballasts or electronic drivers. The type of driver one chooses will depend upon the specific application and the amount of light needed.

Voltage Operating Range

Tubelights are designed to operate within a specific range of AC voltages. This allows one to use them in different electrical systems without needing to buy new bulbs.

High Surge Protection

Many tube lights are designed with high surge protection, which helps to protect the bulb from sudden spikes in voltage. This makes them a great choice for areas where power fluctuations are common.

Optics

Tube lights are available with different optics, such as narrow-angle or wide-angle beams. This allows one to choose the right bulb for one specific application and lighting needs.

By understanding the features of tube lights, one can make an informed decision when selecting the best type of bulb for the project. At Vorlane, we offer a wide selection of tube lights with different features and unique designs for your brand, so you can find the perfect light for any environment.

Raw Materials

While there are a variety of tube light manufacturers out there, they all require some common raw materials in order to produce their products. Here are the most common raw materials used to create tube lights:

Glass or Plastic Enclosures

Tube light enclosures are typically made of either glass or plastic. These protect the gas-filled tube from dirt and moisture, while also helping to evenly distribute light. This helps to ensure that tube lights are bright and efficient.

Quartz or Phosphorus Tube

The gas-filled tube of a tube light is usually made of either quartz or phosphorus. This material helps to convert electrical energy into visible light, making the bulb energy-efficient and long-lasting.

Light-Producing Gases

The gas-filled tubes of a tube light are filled with various gases, such as neon or argon. These gases help to create visible light when electricity passes through them.

Reflector Coatings

Reflector coatings can be applied to the glass or plastic enclosure of a tube light in order to increase its efficiency and light output. This helps to ensure that tube lights are bright and efficient, while also reducing glare.

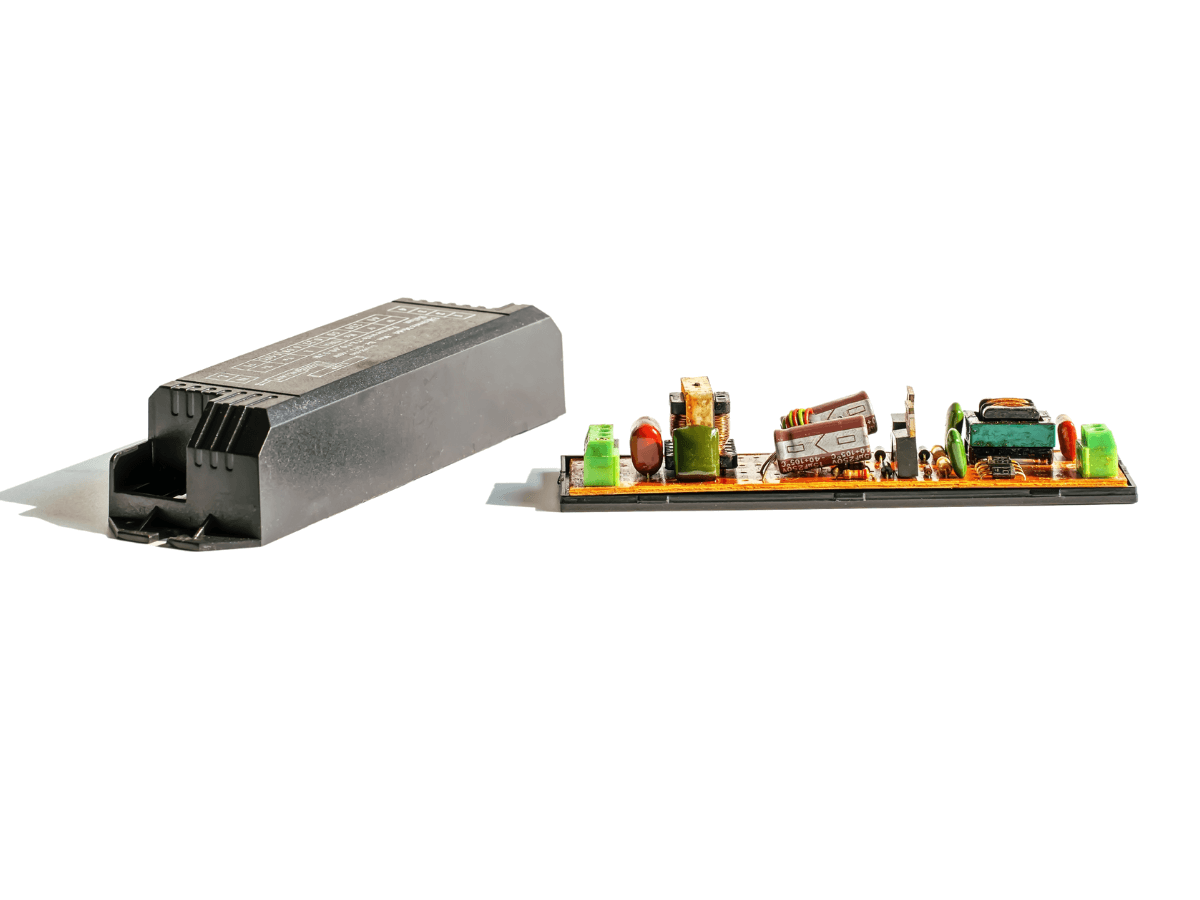

Ballast or Electronic Driver

Tube lights require either a ballast or electronic driver to provide the correct voltage and current needed to power the light. The type of driver used will depend upon the application and the amount of light needed.

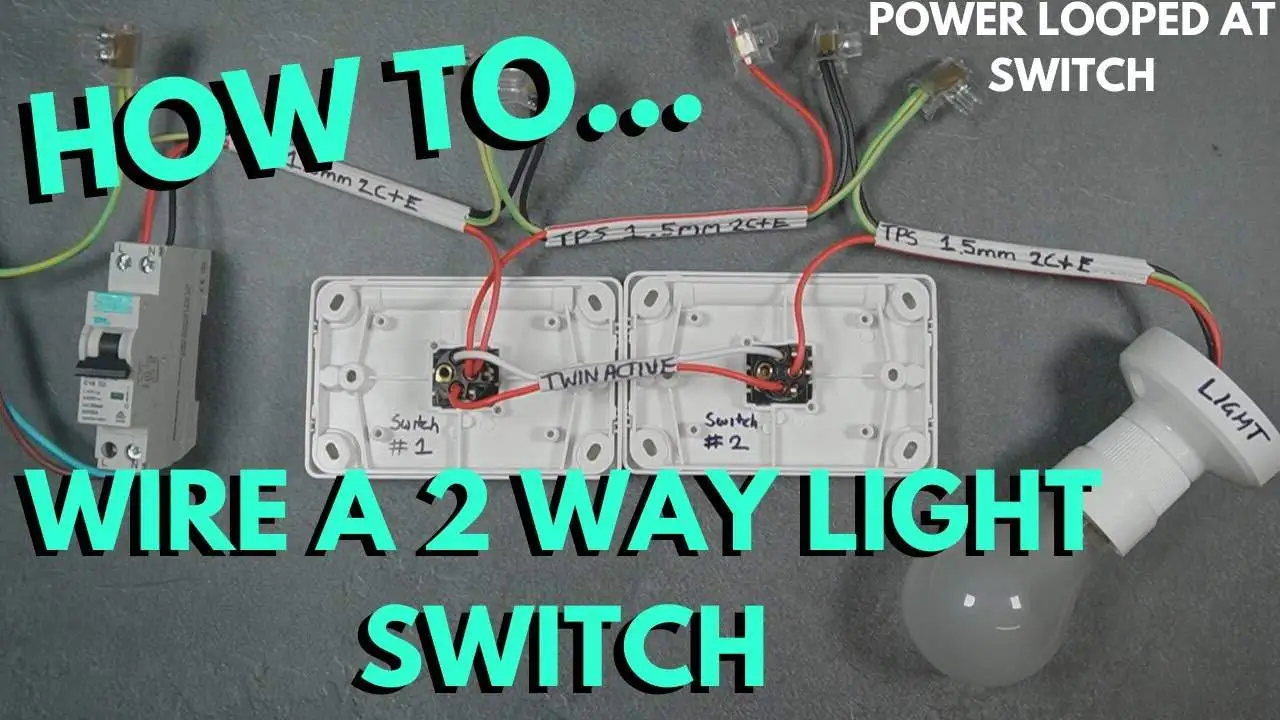

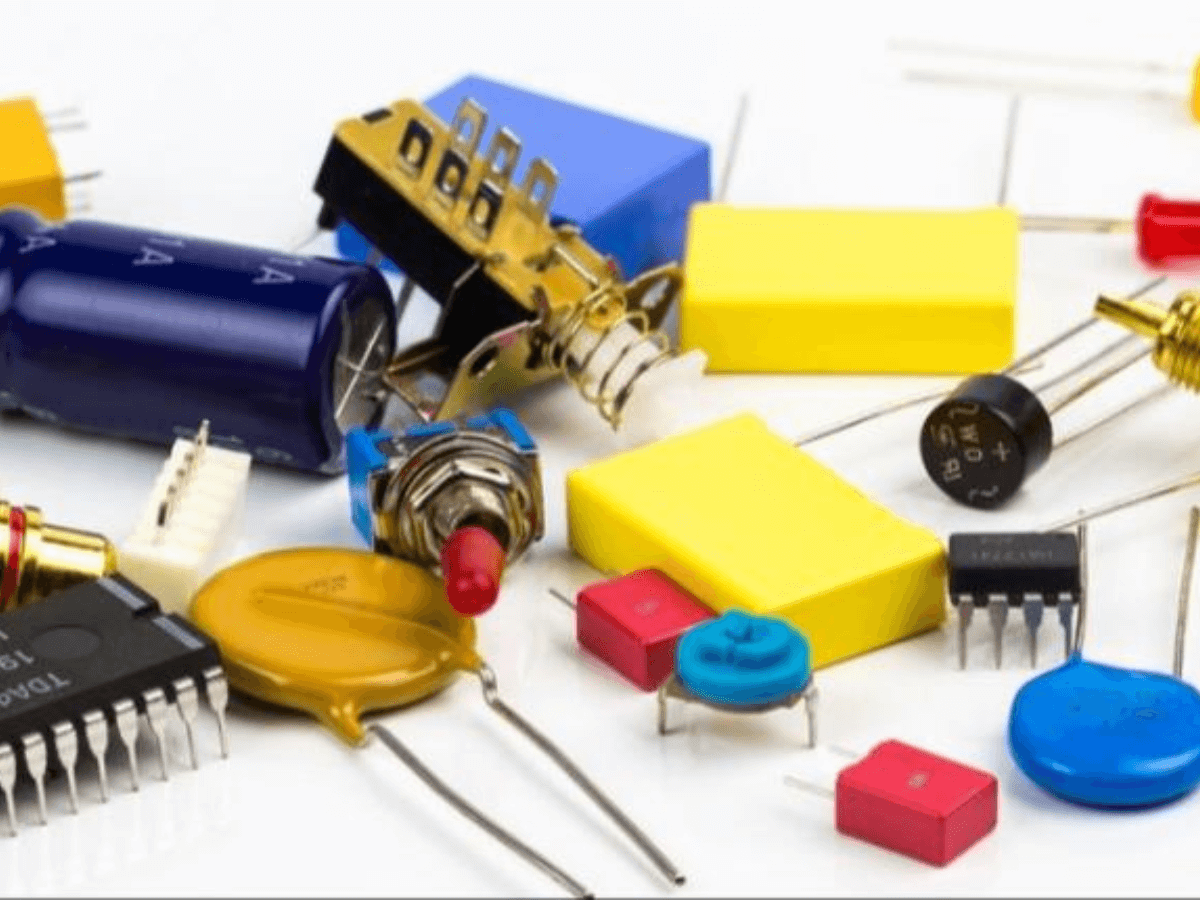

Electrical Components

Electrical components such as wires, sockets, switches, circuit boards, and capacitors are also necessary for the proper functioning of tube lights. They are used to connect the other components in the light and provide an electrical current.

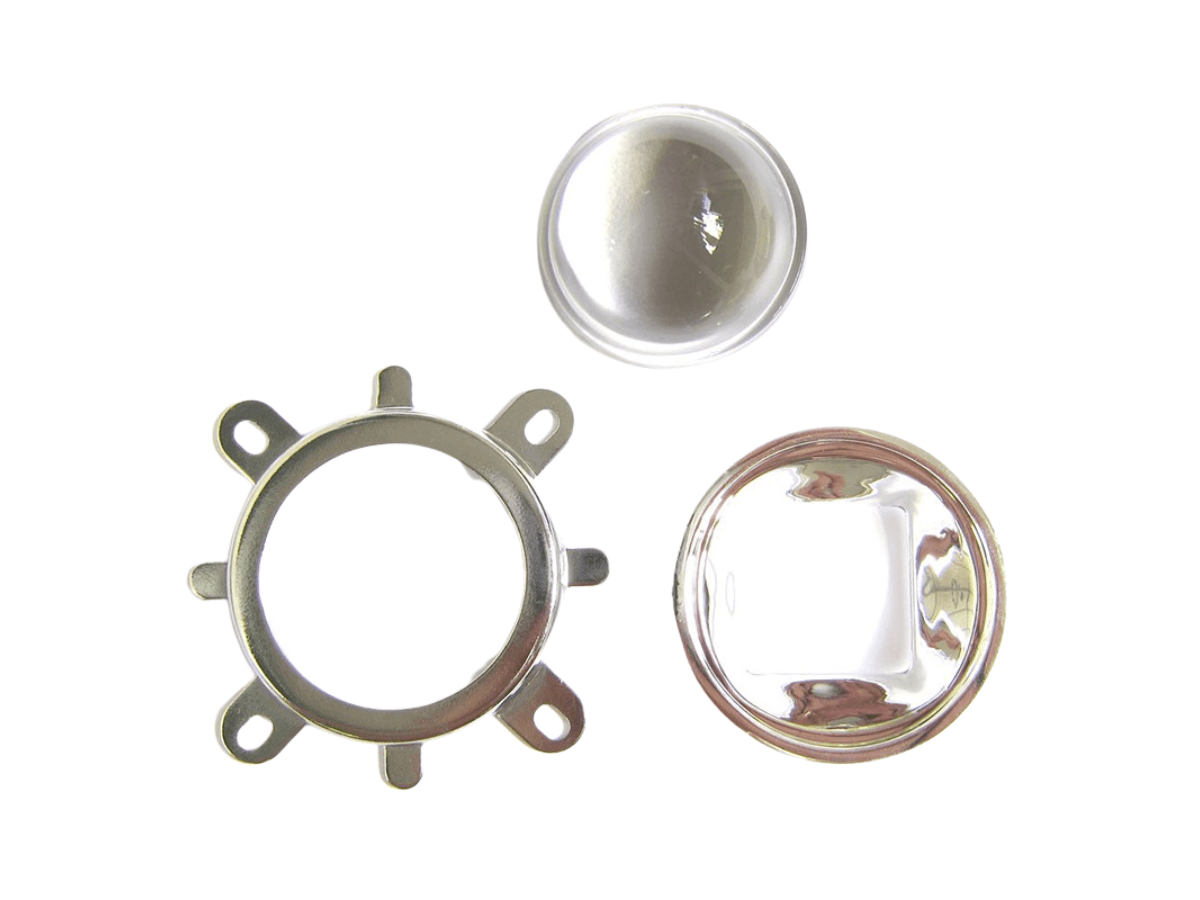

Optics

Optics, such as reflectors and lenses, can also be used to direct the light in a specific direction or area. This makes it easier to control the light output of tube lights and adjust their brightness for different applications.

By using the right raw materials, tube lights can be created to provide efficient and long-lasting illumination. At Vorlane, we ensure that only the highest quality materials are used in all of our products.

The Manufacturing Process

The manufacturing process of tube light is quite complicated and involves a number of steps. Here is an overview of the process:

Step #1 Melting the Glass

The first step in the manufacturing process is to melt the glass. This is done in a furnace that is heated to approximately 2,700 degrees Fahrenheit. The quartz sand, soda ash, and limestone are added to the furnace and melted down.

Step #2 Forming the Glass Tube

Once the glass has been melted, it is formed into a tube. A machine called a drawing tower is used to pull the molten glass into a long, thin tube. The diameter of the tube can be adjusted by changing the size of the orifice through which the glass is drawn.

Step #3 Cooling and Annealing

After the glass tube has been formed, it is cooled and then annealed. Annealing is a process that strengthens the glass and makes it less likely to break. The glass tube is slowly cooled in order to prevent thermal stress cracks from forming.

Step #4 Making the Electrode

The electrode is made by winding tungsten wire around a mandrel (a metal rod). The mandrel is then removed, leaving a hollow tungsten wire coil that can be inserted into the glass tube.

Step #5 Applying the Phosphor Coating

The phosphor coating is applied to the inside of the glass tube using a process called vacuum deposition. In this process, the phosphor material is placed in a chamber and heated until it turns into a vapor. The vapor then condenses onto the surface of the glass tube, forming a thin film of phosphor coating.

Step #6 Assembling the Tube Light

The next step in the manufacturing process is to assemble the tube light. This involves inserting the electrode into the glass tube and sealing it in place with an end cap. The end cap contains a small hole that allows air to enter the tube when it is turned on, allowing the gas inside to ignite and produce light.

Step #7 Testing and Packaging

The last step of the manufacturing process is to test and package the tube light. Quality control tests are performed to make sure that the light meets all safety standards and specifications. The tubes are then carefully packaged for shipment.

Finally, after completing all of these steps, the tube lights are ready to be used in many various applications. Whether one is looking for powerful illumination in a commercial setting or an energy-efficient lighting solution for the business, tube lights are a perfect choice.

Tubelight Manufacturing: Customization and Branding

The tube light is one of the most commonly used lighting fixtures in both commercial and residential settings. While tube light manufacturing is typically a mass-produced process, there is an increasing trend toward customization and branding. So how do companies go about customizing their tube lights?

Here are a few ways in which companies are customizing their tube light production:

Size and Shape

Tube lights come in a variety of sizes and shapes depending on the application. Companies can customize the size and shape of their tube lights to fit specific spaces or create particular lighting effects.

Texture

The texture of the glass is another factor that can be customized. Companies can choose from a variety of textures, from smooth to frosted, depending on the desired effect.

Color

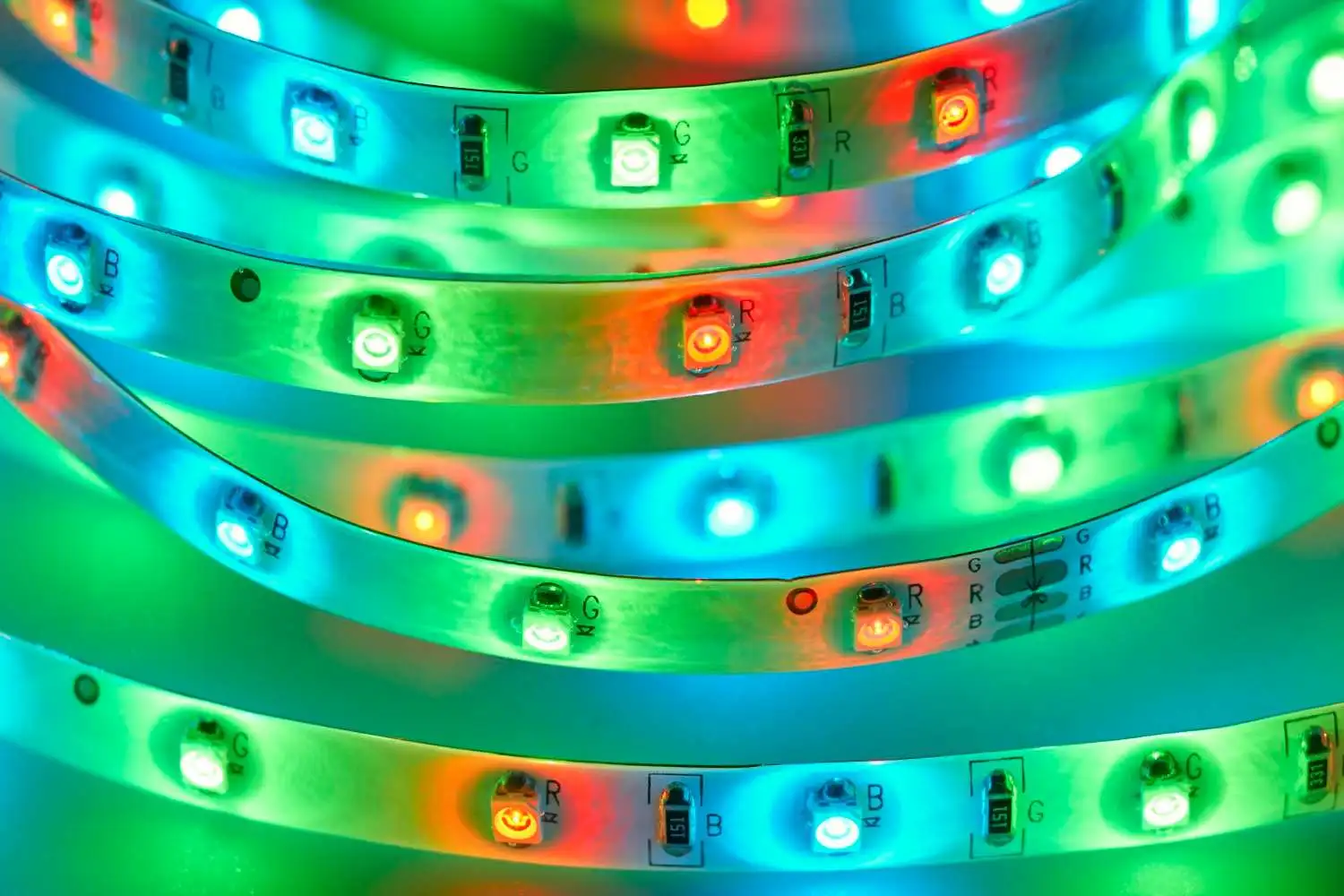

In addition to size and shape, companies can also customize their tube lights by choosing different colors for the phosphor coating. Different colors create different lighting effects and can be used to create the desired atmosphere.

Dimmable Options

Many companies are now offering dimmable tube lights. This allows customers to adjust the brightness of the light and create a more comfortable atmosphere.

Wattage

Different wattage levels are available for tube lights, so customers can choose the best option for their particular application. This allows them to reduce energy costs by using a lower-wattage light when appropriate.

Technology

Companies are also offering tube lights with advanced features such as motion sensors and wireless connectivity. This allows them to create more efficient lighting solutions that can be remotely controlled or adjusted when needed.

Custom Branding and Logos

Some companies choose to add their logos or other custom branding elements to the tube lights. This allows them to create a unique and recognizable brand identity that customers can easily recognize.

Customizing tube light production is an increasingly popular trend, as it allows companies to meet customer needs more effectively and create a unique brand identity. By taking advantage of these customization options, companies can create a product that is tailored to their individual needs and stands out from the competition.

How to Find Tubelight Manufacturer for Your Business

Finding a reliable and experienced tube light manufacturer for your business is essential for producing high-quality products. Before you choose a tube light manufacturer, it’s important to consider their experience and reputation to ensure they can provide the best service possible.

Here are some tips on how to find the right tube light manufacturer for your business:

Attending Tradeshows and Conferences

One of the best ways to find a reputable tube light manufacturer is to attend tradeshows and conferences. Here, you can meet with leading manufacturers, discuss your requirements, and compare products from different companies.

Online Searches

You can also search online for tube light manufacturers in your area. Websites such as Alibaba, Global Sources, and ThomasNet can provide you with a list of local and international companies that specialize in tube light production.

Checking Tubelight Manufacturer Association Lists

It’s also a good idea to check the lists of associations affiliated with tube light manufacturing. These can include organizations such as The National Association of Lighting Manufacturers (NALM), and The International Association of Lighting Designers (IALD).

Referrals

Finally, you can get referrals or recommendations from people in the industry that have worked with tube light manufacturers. Ask for feedback on their experience and find out which companies they recommend.

Finding the right tube light manufacturer for your business is essential for ensuring quality products and successful outcomes. By following these tips, you can easily find a reliable and experienced manufacturer that can meet your needs.

7 Tips for Choosing Tubelight Manufacturer

Are you looking for tube light manufacturers? There are many tube light manufacturers out there, but not all of them are created equal. Here are a few tips to help you choose the right one:

#1 Materials Used

It’s important to consider the materials used by tube light manufacturers when making a decision. Ask them which types of materials they use and how they ensure quality control.

#2 Technology

Find out what type of technology they use to produce tube lights. Look for a manufacturer that uses the latest technologies, such as LED and digital light processing (DLP). LED tube lights are a highly energy-efficient alternative to traditional fluorescent tubes, making them the perfect choice for those looking to reduce energy costs and save money on their lighting bills.

#3 Customization Options

Inquire about customization options available to you when ordering tube lights. Ask if they offer custom colors, shapes, or sizes to make your product unique.

#4 Design Support

Make sure they offer comprehensive design support. Ask if they help with designing and creating custom tube lights to meet your exact requirements.

#5 Energy Efficiency

Look for manufacturers that use energy-efficient lighting solutions. This will help reduce costs in the long run, as well as help lower the carbon footprint.

#6 Certification

It’s also important to check that the tube light manufacturer is certified. This will ensure they are compliant with industry standards and can provide quality products.

#7 Warranty

Finally, ask if they offer any type of warranty. This will provide peace of mind that their products are reliable and can last for a long time.

These tips should help you find the right tube light manufacturer for your needs. Before making a decision, be sure to compare multiple manufacturers and ask questions to make sure they meet your requirements.

The Future of Tubelight Manufacturing

Embracing Sustainability

The future of tube light manufacturing is steering towards eco-friendliness, with a strong emphasis on using sustainable materials and processes. This shift aims to significantly reduce the environmental impact of tube lights, aligning with global sustainability efforts.

LED Technology Integration

A pivotal trend in the evolution of tube lights is the integration of LED technology. This advancement promises enhanced energy efficiency, prolonged lifespan, and superior light quality, all while reducing the reliance on mercury and other harmful substances.

Smart Technology and User Adaptability

Smart technology is set to revolutionize tube light functionality. Features like remote control, adjustable brightness, and color temperature customization will make tube lights more adaptable to individual preferences and contribute to energy conservation.

As tube light manufacturing progresses, the focus on sustainability, technological innovation, and user-centric design is clear. These developments are not just shaping the future of lighting but are also a testament to the industry’s commitment to environmental responsibility and energy efficiency.

Conclusion

All in all, it takes quite a process to make just one tube light. From the sourcing of materials to the final product quality check, there are many stations that a tube light has to go through before it is deemed sellable. We hope this blog post has given some insights into the journey of a tubelight from start to finish.

If you have any further questions or would like more information on our products or services, please don’t hesitate to contact us.